The Benefits of Data Driven Pavement Maintenance

March 3, 2023

By Matt Indihar, Sr Project Manager, WSB

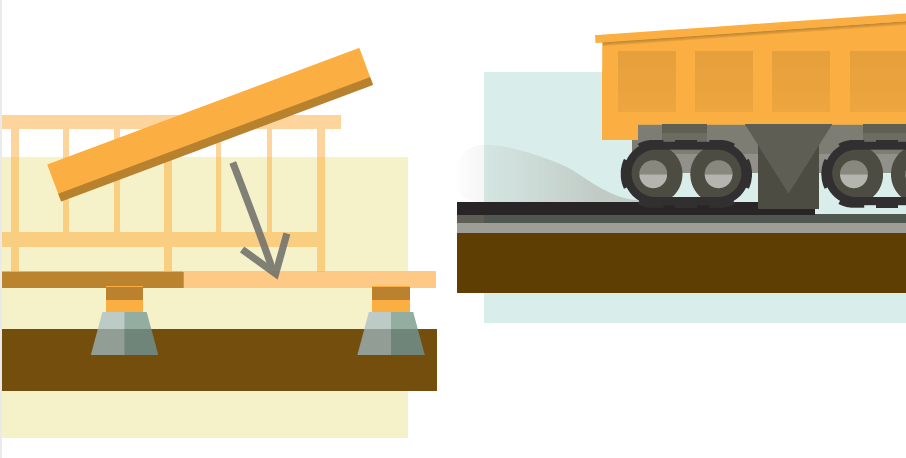

Did you know that the most effective way to manage pavement maintenance in your system is to plan five to ten years in advance? Many municipalities are forced into reactionary pavement maintenance projects. In these cases, decision makers are forced to spend their budgets repairing roads in the worst condition creating large, costly projects. This prevents resources from being allocated towards cost-effective treatments that focus on keeping pavements in good condition before they fail. To get ahead of reactionary maintenance and plan a roadway budget that maximizes the cost-effectiveness of each dollar spent, there needs to be accurate data on the condition of each pavement segment within a system. This provides the necessary information for a data driven pavement management and capital improvement plan to be implemented. Having a pavement network inspection done on a regular basis can bring clarity to condition trends, identify maintenance issues, and allow decision makers to be confident they are implementing the best possible pavement fix at the appropriate time.

Why is this important?

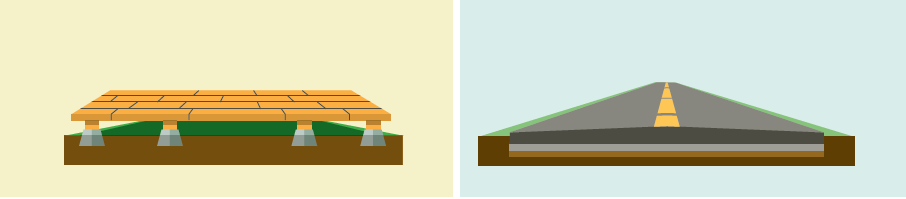

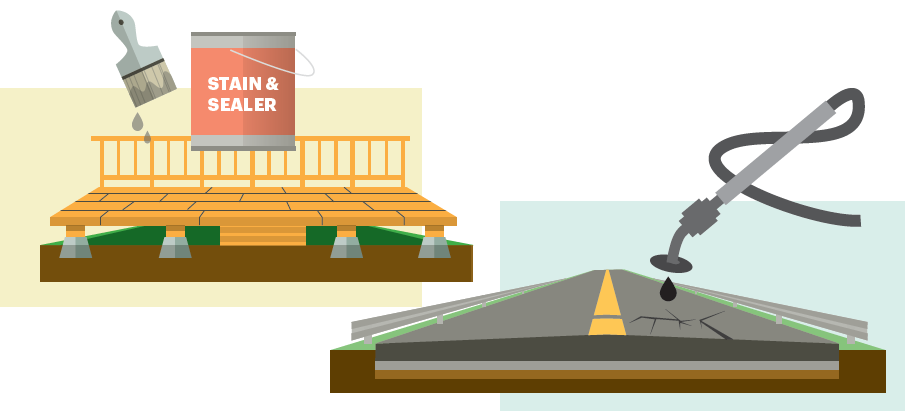

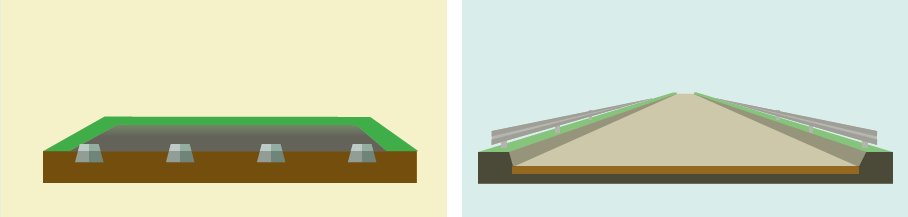

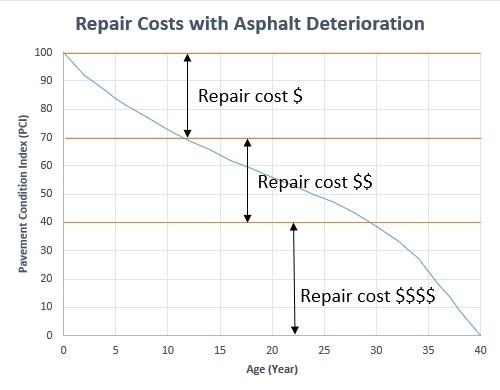

With all of the environmental factors and traffic loads that pavements are exposed to on a daily basis, deterioration is inevitable. With newer or better pavement, only a few distresses may be present so repair costs are lower. However, as pavements age their deterioration continues at an increasing rate. These damaged pavements are more expensive to maintain and may even require major rehabilitation. Knowing the current age, condition, and maintenance history for a pavement section can help determine the most cost effective fix for it based on where it is in its life cycle. Systematic pavement evaluations are one tool network managers can use to monitor their pavement and make the best use of maintenance and construction budgets.

What are pavement inspections and what do they do?

Pavement inspections provide scientific data about the existing conditions of a network of asphalt or concrete surfaces. The process involves a trained inspector evaluating the pavement and cataloging all distress by size, quantity, and severity. With this data, an overall Pavement Condition Index (PCI) can be calculated. This PCI number is a single value that is used to grade the condition of each pavement segment. From there, a report that contains analysis on the condition of the network and a series of recommended solutions for any deficiencies is generated. Additionally, the report may contain specific maintenance recommendations for each road, budget recommendations, trends in pavement conditions, and ideas on how to stretch a limited pavement budget to maximize the overall system condition.

What is the value of a pavement inspection?

A pavement inspection report is a key tool for decision makers to use when determining capital improvement plans and setting budgets. It provides data and rationale to support funding decisions on projects that can be shared with interested parties. The systematic method of determining roadway conditions ensures the most cost-effective and critical projects are being planned for without guessing or relying on personal opinions. In most cases, the cost of implementing pavement inspections pays for itself by optimizing the time and location of pavement repairs. Additional cost savings can be realized when planning the projects 5-10 years out so that similar projects types can be group into larger more cost effective projects.

WSB has the technology and expertise to develop a pavement management plan for your community. Contact us to learn more about a plan for your community.

Matt Indihar is a Sr Project Manager with over 10 years of experience in construction and project development. He leads our pavement management team and has been involved in making pavement decisions in over 50 municipalities, written research based reports on pavement management processes, and participated on technical advisory panels for pavement research and innovation.

[email protected] | 218.341.3614