SUE: What Your City Needs To Avert Disaster

June 17, 2024

By Tony Terrell, Director of Utilities Management, WSB

If your city has an upcoming construction project, using subsurface utility engineering (SUE) can provide numerous benefits, while helping avoid potential catastrophe. In any community, but especially in heavily developed cities, not knowing the exact location of subsurface utilities puts projects at risk and could mean unnecessary delays, unexpected costs, and even harm to communities by temporarily depriving it of water, electricity or gas.

With that in mind, let’s review what SUE is and why your city should think twice about forgoing it.

What Is SUE?

SUE is a service that uses pipe & cable locators, electromagnetic hand-held utility locators, ground penetrating radar, and vacuum excavation to locate and identify utility lines buried beneath the ground. The vacuum excavation process is unique and entails the use of a high-pressure sprayer and a 100-to-200-gallon tank that turns the soil into mud. That mud is then vacuumed out to receive a physical line of sight on utilities buried as much as ten feet below the ground surface. Through vacuum excavation, the exact horizontal and vertical coordinate and the depth of a utility can be measured. The ground penetrating radar is a geophysical method that uses radar pulses to image the subsurface. The GPR can identify different material types underground and is used to locate utilities that are difficult to find, and where the electromagnetic locators had issues. What’s more, SUE uses a quality ranking system that helps construction projects have the right data and a clear understanding of how to avoid colliding with utility lines.

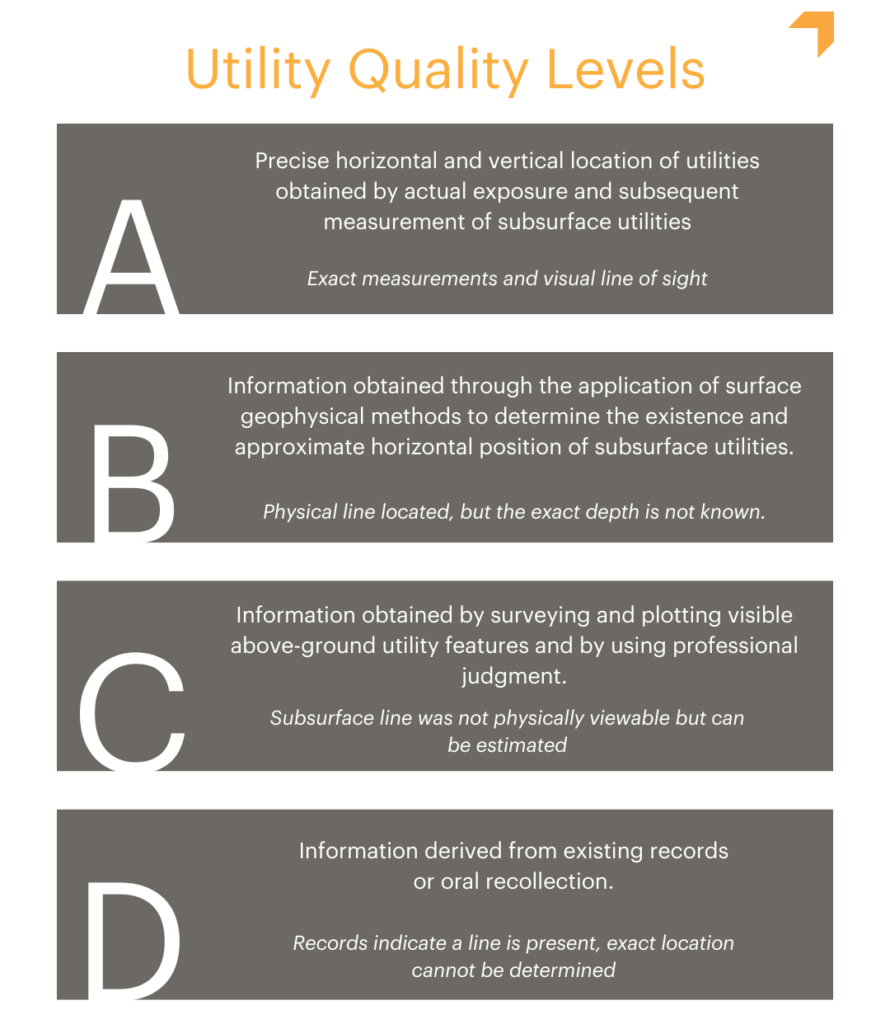

Utility Quality Levels

Using SUE equipment as described above, a utility quality level can then be applied which denotes how precise the location data is. These quality levels fall into four levels of A, B, C and D. Through this quality level scale, design teams and construction teams are better equipped to ensure utilities are not impacted by any excavation work.

The Risk of Forgoing SUE

Forgoing the use of SUE creates the risk of damaging or destroying utility lines. This disruption would not only delay the ongoing project but would also create substantial cost of repairing the utility line and potentially cutting off services to the surrounding community. This is especially critical when working in heavily developed cities with large, condensed populations, and where damaging a utility has the potential of cutting off electrical, water or gas utilities to a large population. Additionally, studies have shown that forgoing SUE services can lead to problems and potential utility damage that will incur costs beyond the initial cost of performing SUE services for a project. On average there is a nearly 5 to 1 cost difference between risking utilities and using SUE to prevent these issues from occurring.

Why is SUE important

- Provides valuable information from which to make valuable decisions for roadway/bridge projects.

- Unnecessary utility relocations are avoided

- Eliminate unexpected utility conflicts typically encountered on transportation projects

- Improved safety

- Reduce project delays, saving time and money

- SUE is a viable technological practice that reduces project costs

How WSB Can Help?

To avert potentially damaging or destroying a utility during construction, cities should reach out to the experienced and talented team at WSB to discuss how SUE will keep costs low and protect not only your project, but the surrounding community. By staying at the forefront of technology and techniques, WSB provides the information and peace of mind cities need to complete their project safely.

Tony has over 30 years of roadway design experience including time at the Oklahoma DOT in the Roadway Design Division. He has worked in bridge design, right-of-way plans, railroad plans, and traffic/traffic signal plans. His work in utility relocation work involved with for all phases of the design, writing right-of-way easements, drawing final utility relocation plans, coordinating the utility relocation, verifying that all utility relocation work has been done and finalized.

[email protected] | 405.808.4127