Magnolia Relief Route

July 18, 2023

By David Balmos, Vice President and Brad Tiemann, SR Project Manager

Relieving the gridlock.

Located in Montgomery County, the 7th fastest growing county in the U.S., is the city of Magnolia, Texas. Well-known for its access to the Texas Piney Woods and sprawling magnolia trees, the city is nestled in the southwest part of the county and is situated along the heavily traveled FM 1488.

For years, the community has been managing severe congestion, safety issues and significant delays at the intersection of FM 1488 and FM 1774. As the city of Magnolia and the surrounding areas continue to experience record growth, the congestion has only worsened. Not only is traffic a concern, but vehicles heading east-west along the corridor need to travel over a railroad, creating another complication.

Solutions to the bottleneck.

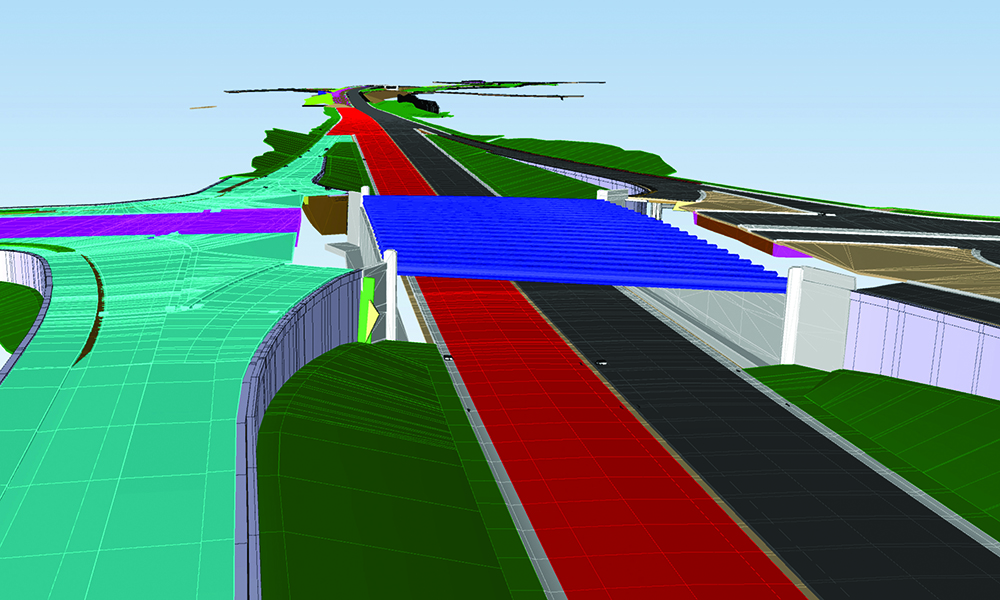

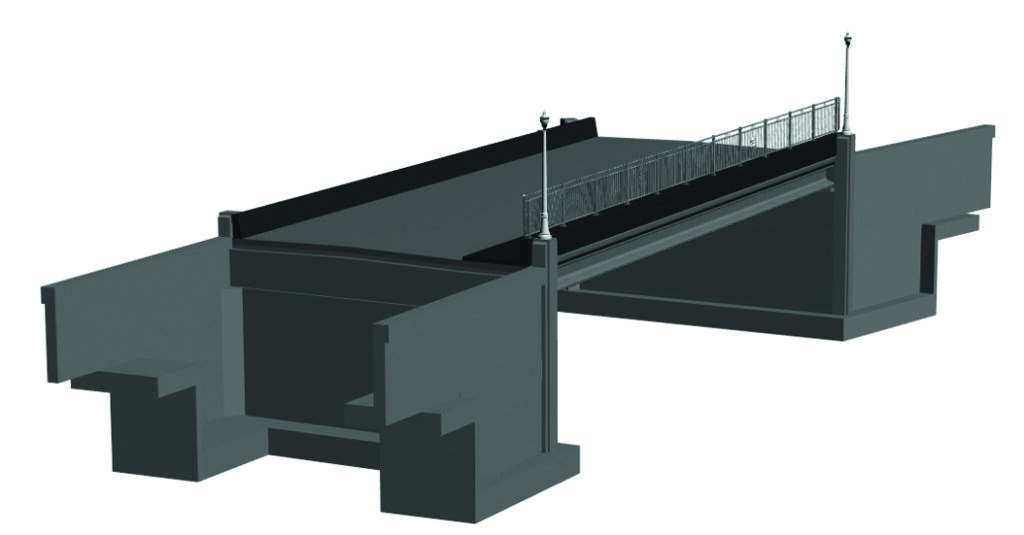

Many ideas have been vetted to alleviate the traffic – most of them resulting in substantial impacts to the historic downtown Magnolia. To ensure the community keeps its economic footing, a bypass around the town was proposed. The $114 million Magnolia Relief Route will include five miles of new four-lane roadways that will extend west from FM 1488, cross over a Union Pacific Railroad track, and connect with the Texas 249 tollway.

Accelerating the timeline.

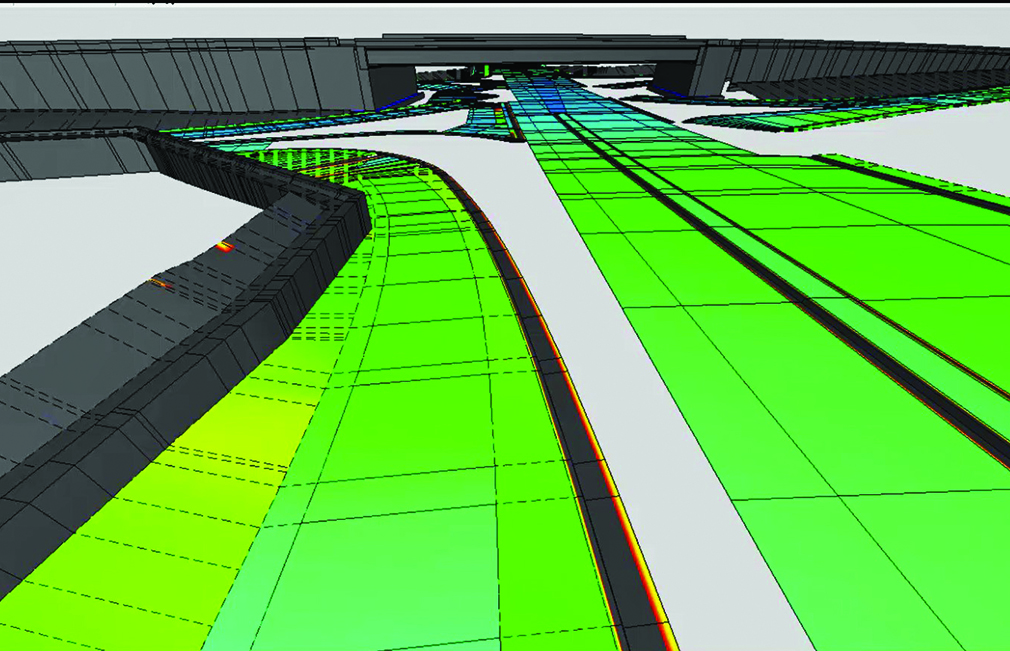

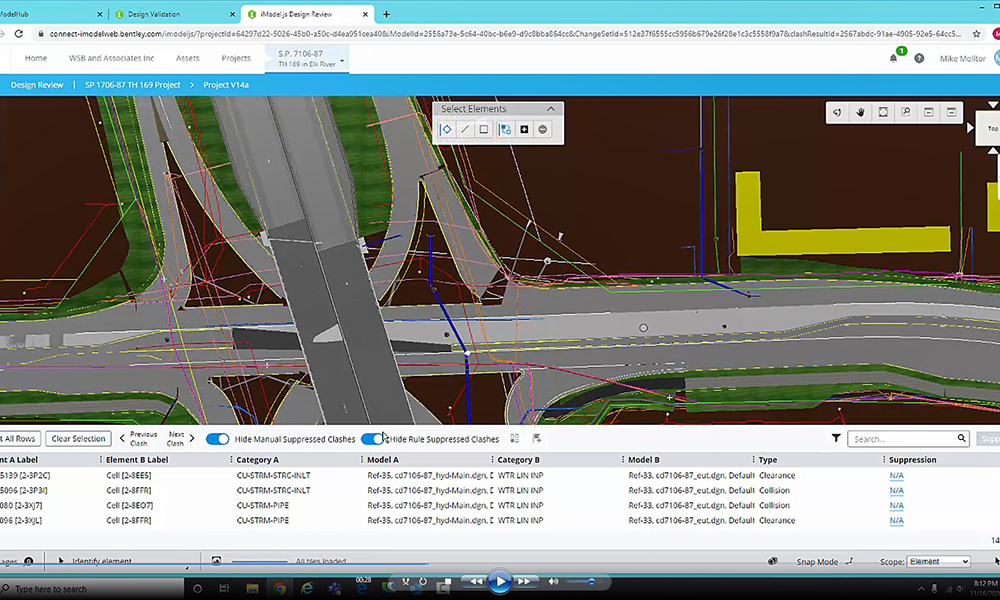

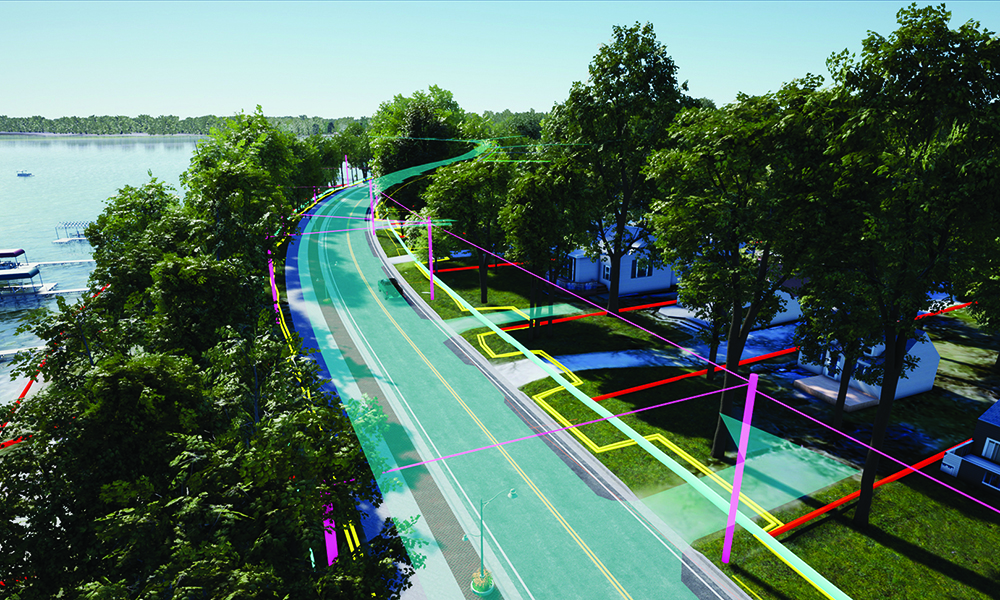

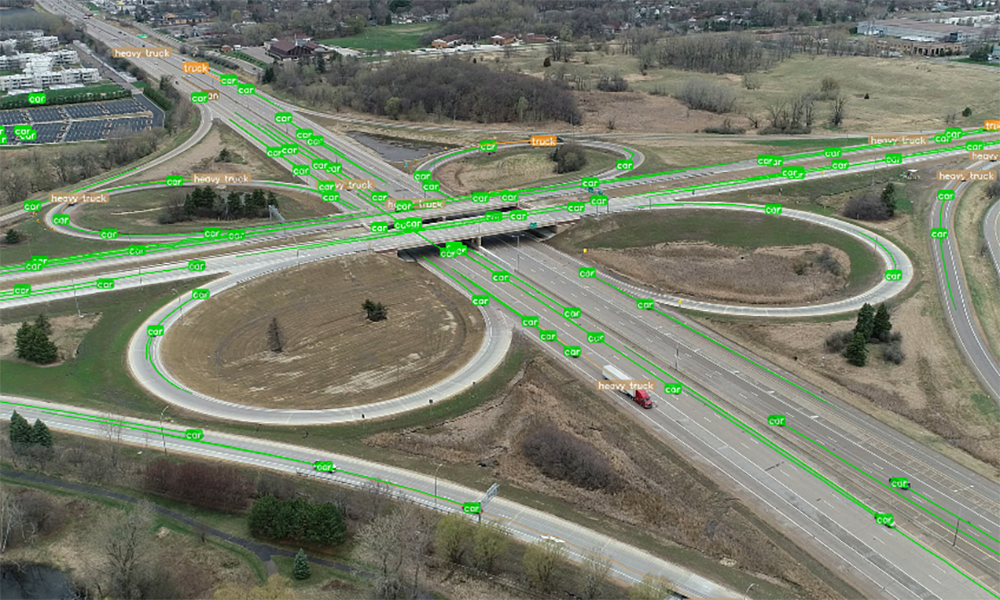

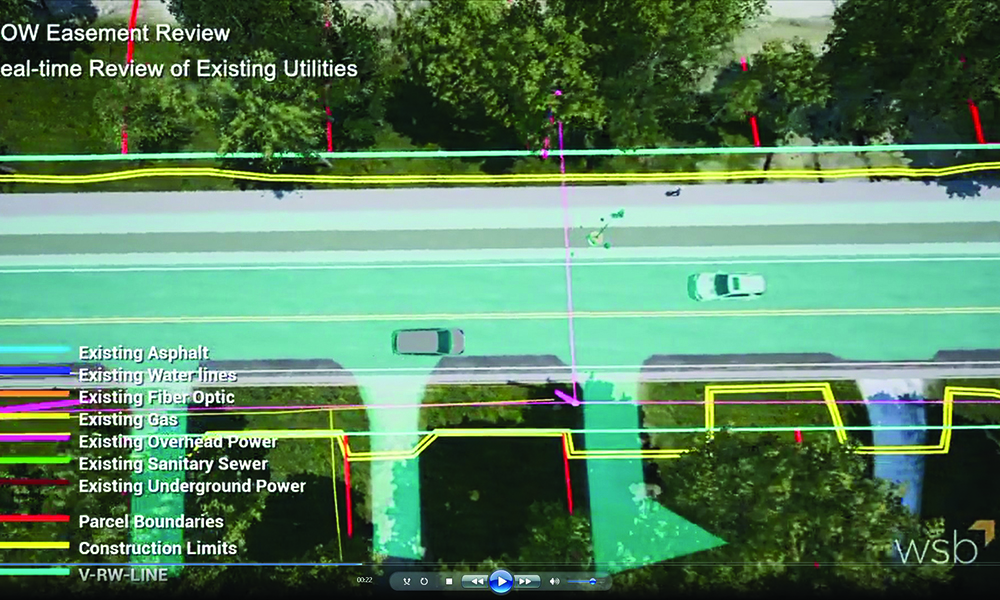

The project has been on the Texas Department of Transportation’s (TxDOT) list for nearly a decade. To accelerate the timeline, WSB is delivering the project through 3D digital delivery. Digital delivery results in efficiencies, and speed that would not be possible through traditional design delivery methods. The timeline from schematic design to final will take less than eight months which will then allow the county and city to have plans finalized when funds become available.

Toll revenue and project funding.

The project will partly be funded through toll revenue from Texas 249, a state-operated toll road. FM 1488 will connect to Texas 249. In Texas, any new facility that brings traffic to the toll road is eligible to be funded out of the toll revenue. Additionally, $10 million was earmarked by Montgomery County as part of the required match in the 2015 road bond. The project is anticipated to be bid in 2024.

Services Provided

- Design

- Environmental Services

- Cost Estimates

- Union Pacific Railroad Permitting & Coordination

- Surveying

- Drainage Studies

By the Numbers

- 5 miles of new roadway

- $114 million project

- 8 month accelerated timeline

- Eliminates 15,000 vehicles each day from crossing the Union Pacific Railroad at-grade crossing.

As Vice President, David will be responsible for driving business and working across many markets in the region including the department of transportation, toll road authorities, county government agencies, transit authorities, port authorities and local municipalities. In addition, David will support projects in the private sector, working closely with land developers, commercial interests, oil and gas and pipeline transport.

Brad is a Senior Project Manager with 30 years of engineering experience in the design, construction and maintenance of transportation facilities. He has led the development, preparation and plan review (QA/QC) of more than 100 separate PS&E packages including urban arterials, municipal streets, rural highways and bridges. He has considerable experience with maintenance and construction for transportation facilities in Texas, and as a recent TxDOT retiree, Brad has a strong understanding of the Texas transportation system.