By: Jared Langley, Remote Sensing Manager, WSB

October 24th, 2025

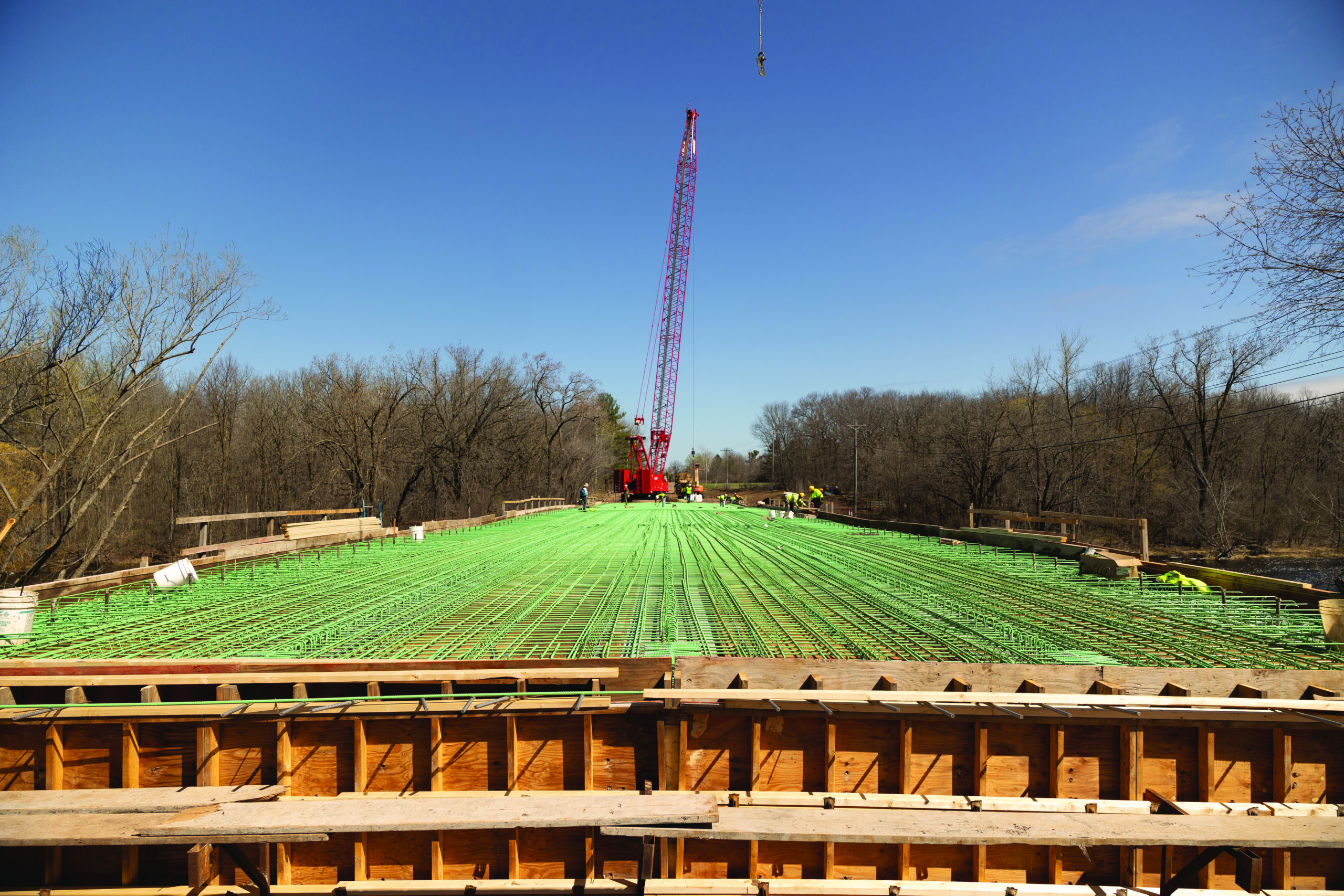

Surveying has long been the foundation of successful infrastructure development. Traditionally reliant on boots-on-the-ground fieldwork, the discipline is now undergoing a transformation driven by remote sensing technologies. These innovations are reshaping how data is collected, analyzed, and applied across the lifecycle of infrastructure projects.

Transforming Traditional Surveying

Remote sensing refers to the use of aerial and terrestrial-based technologies—such as LiDAR (Light Detection and Ranging), photogrammetry, thermography, and mobile mapping—to gather spatial data without direct contact with the surveyed area. This approach offers significant advantages such as reducing time in the field, enhancing safety, and delivering high-resolution data that supports more informed decision-making.

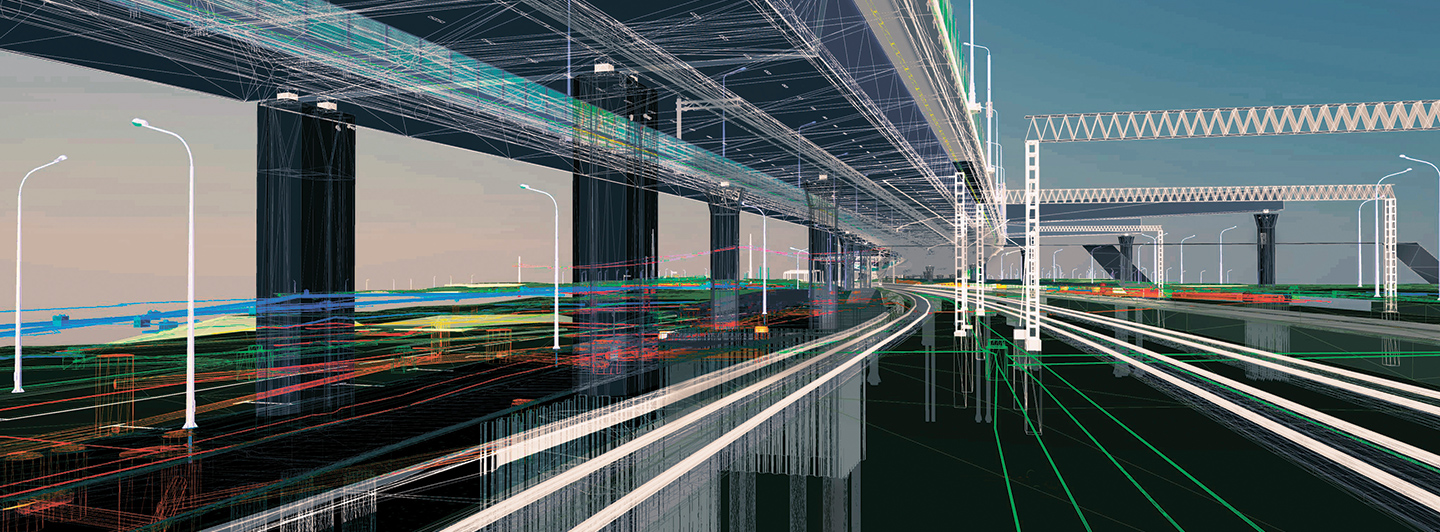

One of the most impactful applications of remote sensing is in topographic mapping. Aerial LiDAR, for example, can scan vast areas in a fraction of the time required by traditional methods, producing detailed 3D models that inform design and engineering. Mobile mapping systems mounted on vehicles allow for rapid corridor data collection, even in high-traffic or hazardous environments. These tools are particularly valuable in transportation, utility, and environmental projects where precision and efficiency are critical.

Beyond mapping, remote sensing supports change detection, asset monitoring, and environmental analysis. Thermographic imaging can identify heat loss in buildings or detect structural weaknesses, while magnetometry helps locate subsurface utilities and anomalies. These capabilities enable proactive maintenance, reduce risk, and improve long-term asset performance.

Integrating Remote Sensing into the AEC Workflow

The broader AEC industry is increasingly integrating remote sensing into its workflows. As infrastructure projects grow in scale and complexity, the demand for accurate, timely data is rising. Remote sensing meets this need by offering scalable solutions that align with digital project delivery models, including BIM and GIS integration. It also supports sustainability goals by minimizing field disturbance and enabling better environmental stewardship.

While remote sensing doesn’t replace traditional surveying, it enhances it—providing a complementary layer of intelligence that improves outcomes across planning, design, and construction. The key to unlocking its full potential lies in combining technical expertise with the right tools and workflows.

Leading the Shift to Smarter Surveying

The future of surveying is remote, digital, and data-driven. As we continue to push boundaries and embrace emerging technologies, WSB remains focused on what matters most: empowering our clients with clarity, confidence, and a competitive edge in every project.

WSB supports this evolution by offering comprehensive remote sensing services tailored to our clients’ needs. Our team integrates advanced technologies with deep industry knowledge to deliver data-driven solutions that improve project efficiency, safety, and quality. Whether through aerial LiDAR, mobile mapping, or AI-enhanced utility detection, we help clients harness the power of remote sensing to build smarter, more resilient infrastructure.