April 4, 2024

Last week, WSB announced a new partnership with 4M Analytics to advance infrastructure programs and projects with real-time utility data. Andy Kaiyala, VP of Digital Construction Management and Controls at WSB, and Joe Eberly, Vice President of Growth & Sales Strategy at 4M Analytics, recently addressed the benefits of the partnership and what it will mean for our clients and partners.

Q: What does this mean for the industry?

Andy: WSB continues to build out a comprehensive Digital Construction Management (DCM) offering to better serve our clients, and this partnership with 4M Analytics is another step forward. Every construction project must consider what lies beneath the ground. 4M is applying cutting edge technology to this significant problem, delivering the best data, and making it available faster than any other firm. This does not take the place of field investigation, but rather informs those investigations to be more precise and reliable. Everyone wins in this.

Joe: With utility risk as one of the primary challenges in the industry, the WSB/4M partnership advances the mitigation efforts to the earliest stages of the project planning lifecycle and at the lowest risk point. It also provides significant improvements in the time and cost of accessing utility records and data used in the early feasibility, coordination, pre-construction, and preliminary design processes on infrastructure projects.

Q: What does this mean for 4M’s clients?

Joe: The partnership will signal to the 4M Analytics client base that our utility data can have a much larger impact on their internal processes and create a vision for how the data can be used to support their project lifecycle workflows and development requirements.

Andy: Despite increased awareness and heightened attention, our industry continues to see an upward trend in utility strikes (Common Ground Alliance). These cost billions of dollars and most critically put people and lives at risk. Better information delivered timely across the life cycle of a project, from planning to construction, will help all parties mitigate this serious risk, deliver projects safely, on time, and on budget. This is what DCM is all about. Helping you be safe, deliver with the highest quality, and do so while protecting your bottom line and beating the schedule.

Q: How quickly will this partnership have an impact?

Joe: The partnership will have an immediate market impact and will increase our messaging efforts to support our clients and the industry more broadly and bring awareness that the conventional methods of construction delivery are no longer sustainable in a market where time and resources are becoming scarcer.

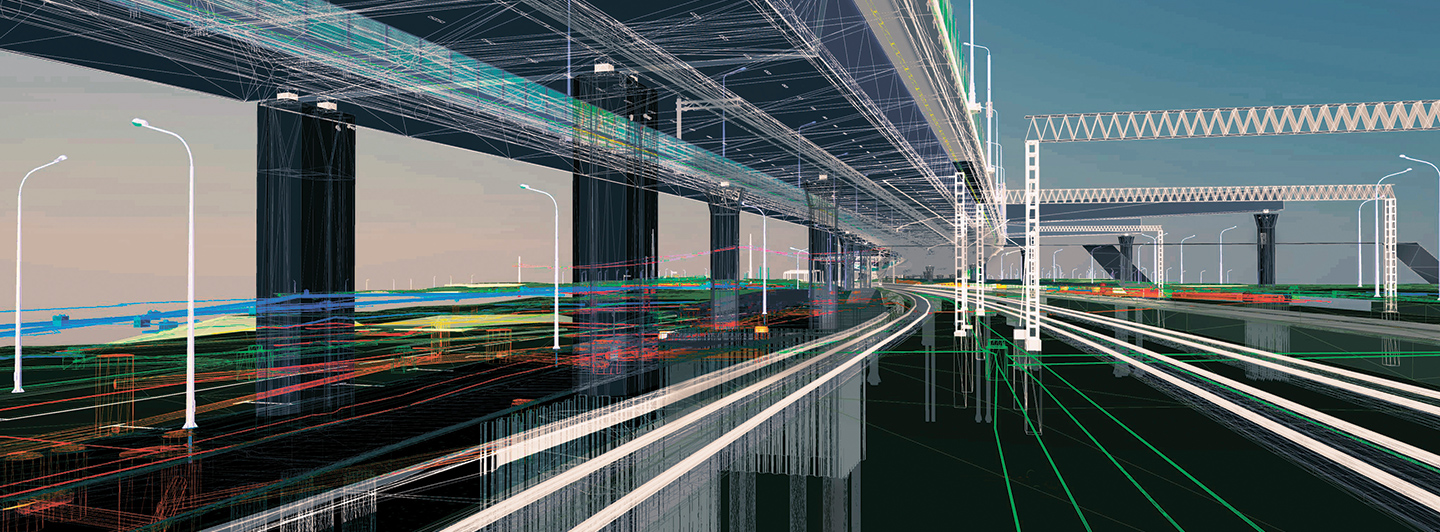

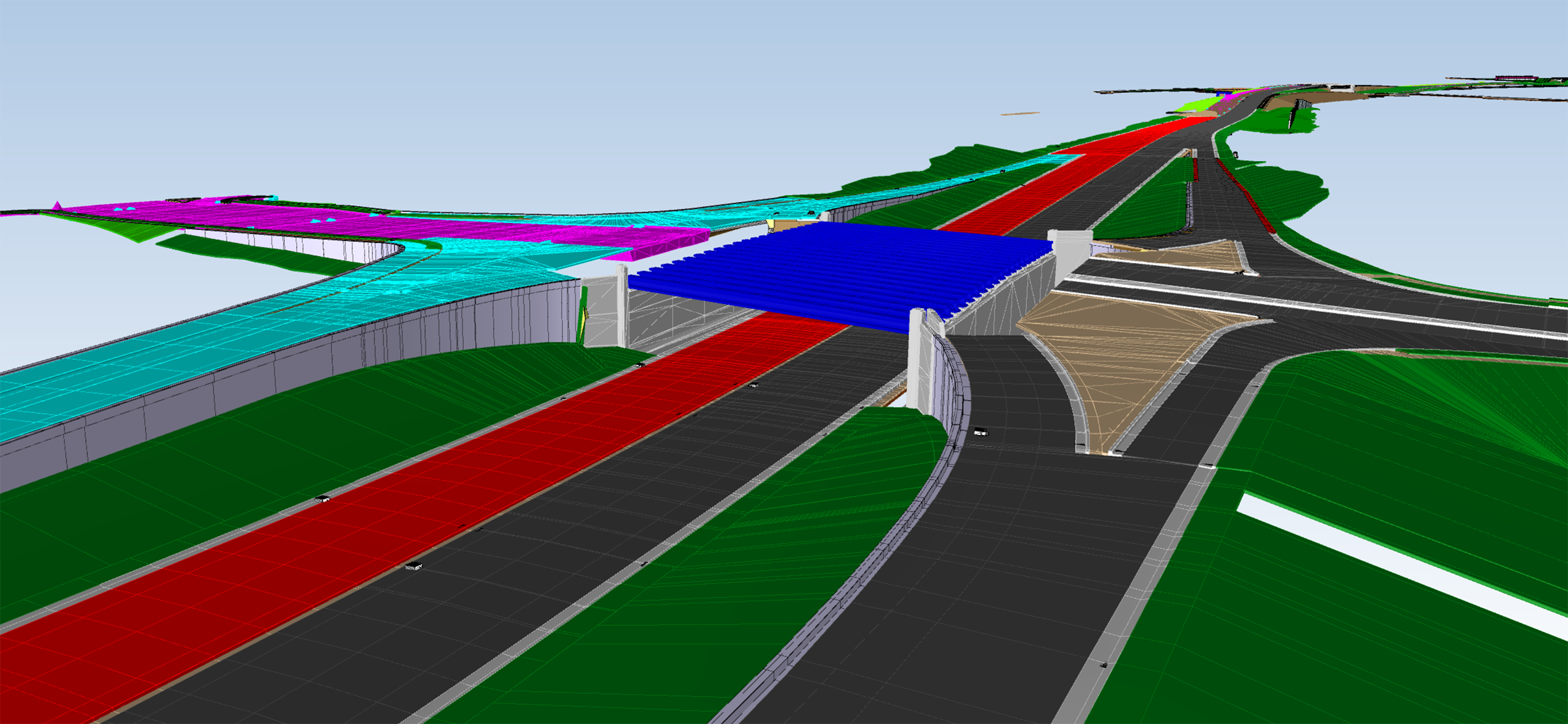

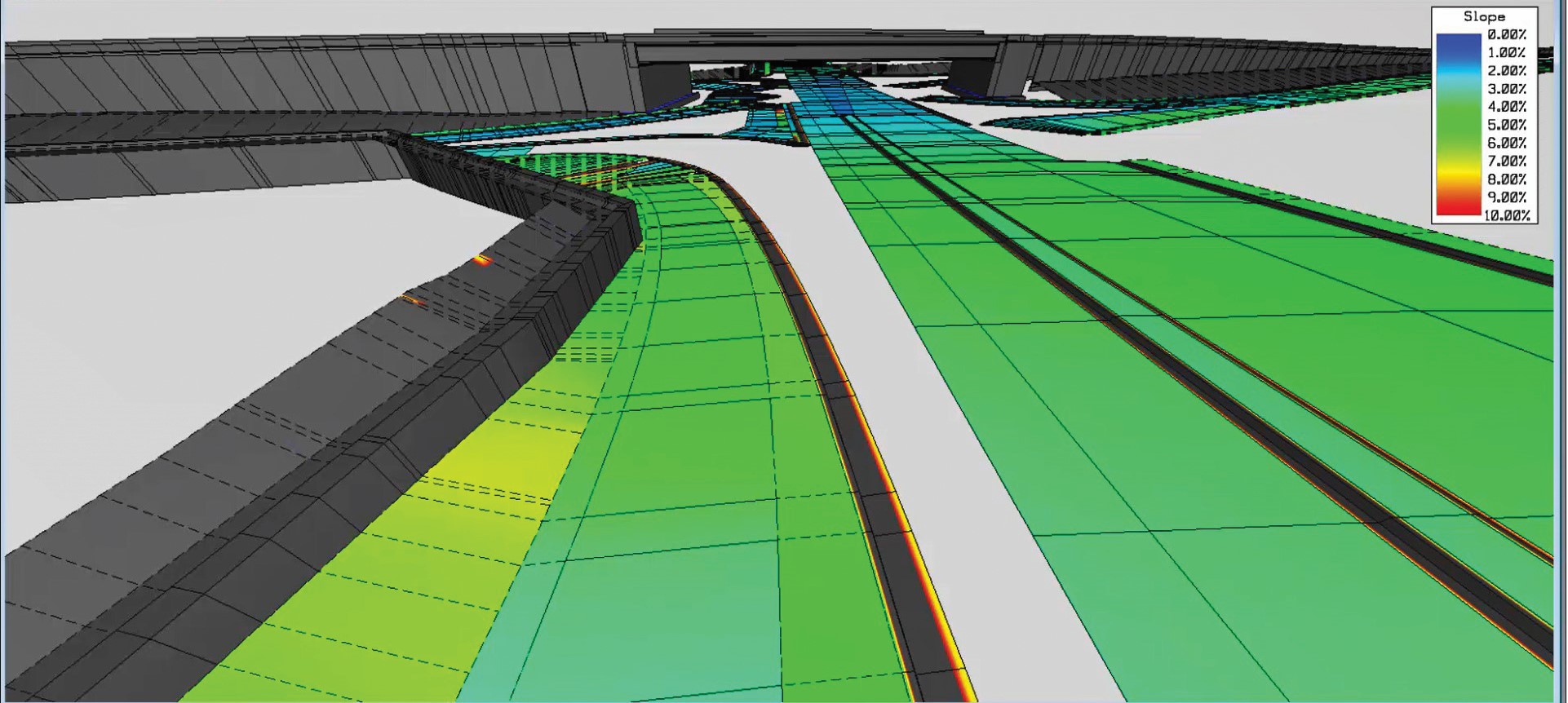

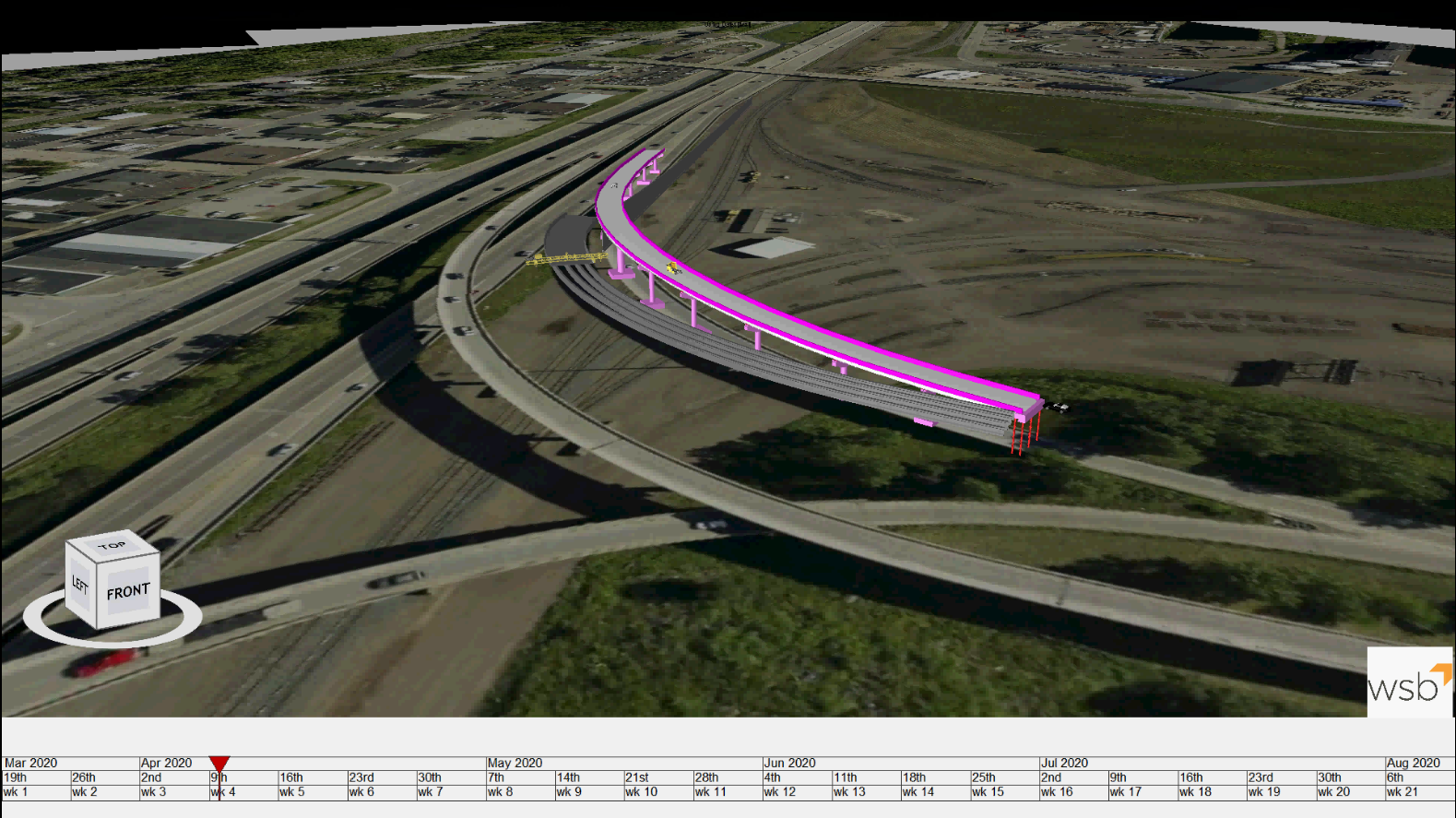

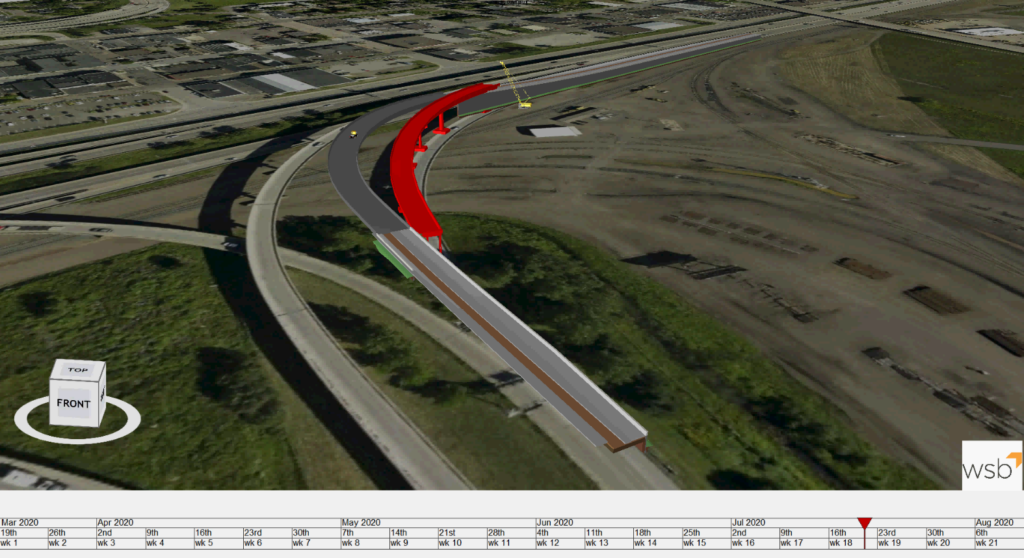

Andy: It already is. We are incorporating the 4M data into 3D models for constructability review, means and methods, risk analysis and mitigation, schedule review, design conflict resolution, and more. We really are putting the design model to work, and how would you do that without the best subsurface data available quick enough to make a difference? Our position is that you can’t, and the sooner more owners and contractors begin deploying this solution, the better off the industry will be.

Q: How does this partnership work between the two companies?

Joe: The 4M partnership adds a layer of usability and value to the WSB DCM delivery model. Specifically, the ability to enhance the DCM 3D modeling services on the Bentley Platform. The result is a seamless delivery of data that can connect the office to the field, saving time and money along the way while reducing risk and improving decision making.

Andy: Through 4M advanced technology we can quickly and efficiently bring subsurface utility data into our digital representation of the future physical asset – into the digital twin. We then publish that data into SYNCHRO, leveraging another of our partnerships with powerhouse technology provider Bentley Systems, and start making better decisions. Seamless access to all the critical information you need to plan, design, bid, win, and build the work.

Q: Why is this happening now? Why this partnership?

Andy: The time is now. We must work quickly to address utility conflict and coordination, one of the most significant risks in our industry. 4M brings the technology and the data, and our WSB team leverages that information to better deliver our projects safely, on time, on schedule, and with the quality WSB is known for.

Joe: The scope and scale of the utility data challenge, and the inherent risk, have now been matched by 4M’s ability to apply its utility AI mapping technology at the same scale. 4M and WSB delivers reliable, real-time, and validated utility data for any project in the U.S. — right from your office.

Joe Eberly is the Vice President of Growth & Sales Strategy at 4M Analytics, Inc. and has more than 25 year’s experience in Construction Technology, serving the Public and Private Owner, Engineering and General Contractor markets. Prior to joining 4M, Joe served as the VP of Sales at e-Builder, a Capital Construction Management Software, which was acquired by Trimble in 2018. At Trimble, Joe was responsible for Sales, Account Management and Customer Success for the Owner & Public Sector and led the GTM launch for ProjectSight, a Project Management platform for General Contractors. Before entering the technology world, Joe was a Superintendent and Warranty Manager for a top-10 development company in the residential building market and owned a consulting firm focused on construction material management and value engineering services. Joe lives and works from Denver, Colorado and enjoys spending time with his grandkids.

Andy Kaiyala is the Vice President of Digital Construction Management and Controls at WSB. With over 20 years of experience and an emphasis on large, complex, alternative delivery infrastructure projects in the transportation, heavy civil, flood control, and transit spaces, Andy brings a wealth of knowledge and expertise. At WSB, Andy leads the firm’s DCM initiative as the AEC industry is recognizing the value of digital delivery. Prior to joining WSB, Andy was responsible for domestic and international bidding and proposal efforts for Lane Construction Corporation. Andy’s career focus has been to deploy a full project life-cycle approach to business strategy that facilitates stakeholder involvement and achieves project schedule and delivery certainty. He currently works out of WSB’s Dallas office and guides clients through a process that mitigates risk and reduces conflict for all stakeholders.